EN14103 Teor de éster metílico de ácido linolênico e éster metílico de ácido graxo por GC

Marca KN

A Origem do Produto Dalian, China

O tempo de entrega entregar assim que receber o pagamento

A capacidade de abastecimento 30 séries por mês

O biodiesel especificado deve ser ésteres monoalquilicos de ácidos graxos de cadeia longa derivados de óleos vegetais e gorduras animais.

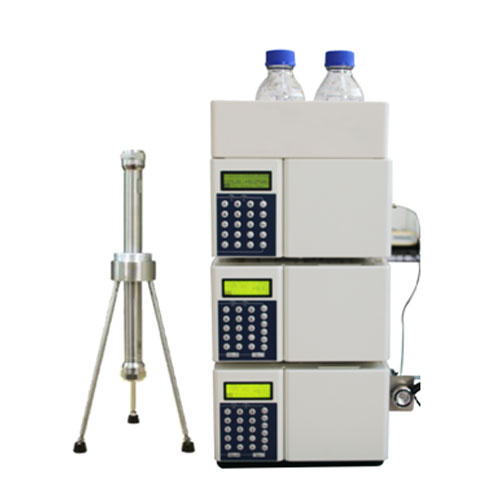

KN-Biodiesel GC Plus Gas Chromatograph

Introduction

Interest in biodiesel as a clean-burning alternative fuel produced from renewable sources such as vegetable oils has increased tremendously over the last few years, mainly due to its reduced environmental impact in comparison with conventional petro-diesel. Biodiesel can be used as a pure fuel or blended at any level with petroleum diesel. In order for biodiesel to be commercialized as pure biofuel or blending stock for heating and diesel fuels, it must meet a set of requirements defined in ASTM D6751 and EN 14214 standard specifications. These standards indicate the maximum allowable concentrations of contaminants in pure (B100) finished product, along with other chemical-physical properties necessary for a safe and satisfactory engine operation.

KN-Biodiesel GC Plus Gas Chromatograph

ASTM D6584 Standard Test Method for Determination of Total Monoglyceride, Total Diglyceride, Total Triglyceride, and Free and Total Glycerin in B-100 Biodiesel Methyl Esters by Gas Chromatography

EN14103 Fat and Oil Derivatives-fatty acid methyl esters FAME determination of ester and linolenic acid methyl ester contents

EN14110 Fat and oil derivatives - Fatty Acid Methyl Esters (FAME) - Determination of methanol content

Instrumentation and Reagents

The analysis of glycerin, mono, di and triglycerides by gas chromatography (GC) requires a non-discriminative injection system able to transfer both volatile and heavy compounds without discrimination or degradation. A TRACE GC Ultra equipped with a true cold On-column inlet and a flame ionization detector (FID), automated by a TriPlus Autosampler for liquids was used, controlled through the Thermo Scientific Chrom-Card data system. The true cold On-column injector offered on the TRACE GC Ultra is a permanently cold system, able to prevent discrimination of the heavier fraction and to eliminate any risk of degradation of labile components like triglycerides, thus granting excellent recovery and proven sample integrity.

The analytical column used is a non-polar Thermo Scientific TRACE™ TR-BIODIESEL(G), 10 m, 0.32 mm ID, 0.1 μm f.t. This column is designed to provide excellent performance for this high temperature GC method, featuring enhanced mechanical robustness at high oven temperature, and thus prolonged lifetime. A 1 m x 0.53 mm ID pre-column is used, connected to the column by a leak-free high T purged connection.

A low dead volume leak-free metal tee has been specifically conceived for a reliable connection between the guard column and the analytical column at high temperature operation, preventing from the use of normal glass press-fit unions. Such a connector has proven to stay leak-free even with extremely large and frequent oven temperature variations (Figure 2).

Calibration is achieved by the use of two internal standards – 1,2,4-butanetriol (IS1) for glycerine and tricaprin (IS2) for mono-, di- and tri-glycerides, and four reference compounds – glycerin, mono-olein, di-olein and tri-olein.

Because glycerin and mono- and di-glycerides are polar and high boiling components, they must be derivatized to increase their volatility and reduce activity before injection into the GC. The method requires derivatization with MSTFA (N-methyl-N-trimethylsilyltrifluoroacetamide) in pyridine, which transforms these compounds into more volatile silylated derivatives. Below is a list of required reagents:

MSTFA (N-methyl-N-trimethylsilyltrifluoroacetamide)

n-Heptane

Pyridine

1,2,4-Butanetriol – internal standard solution 1,1 mg/mL in pyridine (IS1)

1,2,3-Tricaproylglycerol (tricaprin) - internal standard solution 2, 8 mg/mL in pyridine (IS2)

Reference materials: glycerol (glycerin), 1-monooleoylglycerol (monoolein), 1,3-di-oleolglycerol (diolein), 1,2,3-tri-oleoylglycerol (triolein)

Mono-glycerides check mix (monopalmitin, monostearin and monoolein), in pyridine Figure 2: Leak free high T purged connector

Main Features

KN-GC-9600 Plus adopts 10.2 inch touch LCD. It can display the temperature of each way and Real-Time Operation conditions, so as to achieve the on line monitoring

POST, independent temperature control of six ways and five stages program temperature rise 3. Self-diagnosis function: If there is a failure, the apparatus will automatic display the fault phenomenon, code and cause to help the operator find and solve the fault in short time

超温保护:保护温度可自由设定,若有办法超过设定温度,仪器将自动断电并报警

载气保护:当载气有压力时,仪器会自动断电停止加热,有效保护色谱柱和热导检测器

智能模糊控制背门系统:自动跟踪温度,动态调节背门角度。该仪器可在室温条件下进行精密控制。

配备填充柱柱状进样、搪玻璃进样和具有膜清洗功能的毛细管分流/不分流进样装置。仪器还可加装气体取样器

高精度和稳定的双路。最多可安装4种探测器

先进的气体程序,可使用氢气火焰检测器和热导检测器。

FID 和毛细管入口均受 EPC 控制

可选择电子流量压力显示系统和内部工作站装置

19位自动液体取样器

技术参数

温控指标

1、控温范围:室温5℃~400℃,增量:0.1℃

2、控温精度:优于±0.1℃

3、程序升温:5段,段间恒温时间:0~999min

增量:0.1min,温度增量:0.1℃

升温速率:200℃以下最大40℃/min

200℃以上最高20℃/min

细节层次

化合物 | 最大% m / m (EN 14214) |

甘油 | 0.02 |

甘油单酯 | 0.8 |

Di-glycerides | 0.2 |

甘油三酯 | 0.2 |

总甘油 | 0.25 |